Measuring at the scene of the event

- Provision of seamlessly integrated sensors

- Enabler for megatrends such as Internet of Things, Smart Factory, Smart Home and Ambient Assisted Living

The IFM ...

- develops sensors and sensor systems based on different physical principles and technologies.

- brings sensors as close as possible to the place of application through competence in microstructure technology (miniaturization, adaptation to the installation space, reliability under harsh environmental conditions).

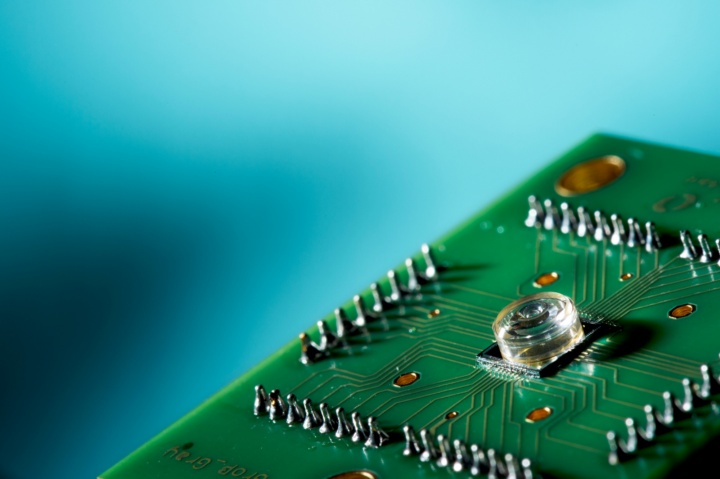

Optical components and system integration

- Non-contact measurement

- High transmission speed of information

- Innovative sensors (e.g. quantum sensors)

The IFM ...

- provides a portfolio of microoptical components (microlenses, diffractive elements, hybrid optical elements, micro mirrors and waveguides).

- opens the door to active alignment and high-precision assembly of optics.

- develops optical sensors.

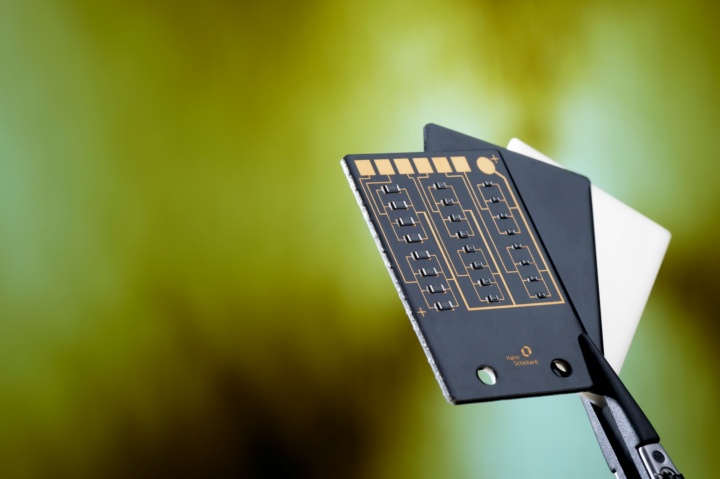

Using digital process chains for manufacturing.

- Economical production of products from batch size 1

- Individualized products, small quantities, large number of variations

The IFM ...

- opens up digital process chains on the basis of additive and subtractive 2D and 3D processes (direct exposure, printing technologies, laser technologies).

- proves their reliability.

- increases the maturity level of rapid prototyping to rapid manufacturing.

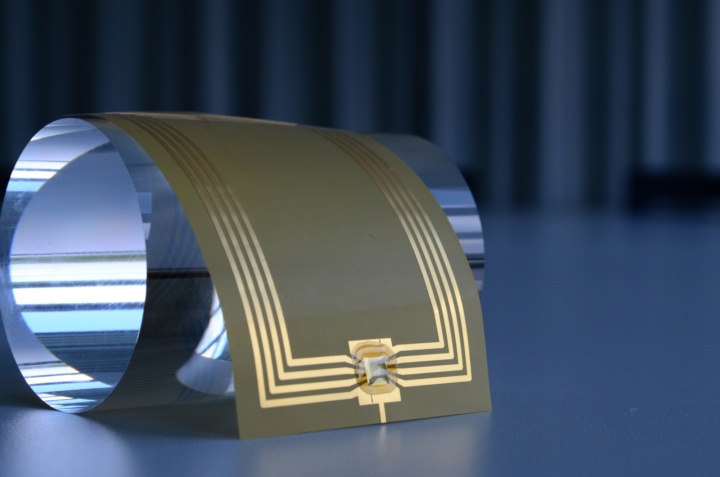

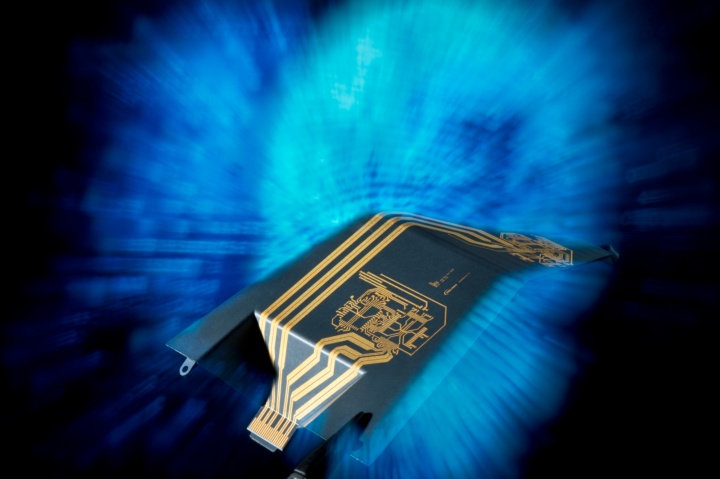

Ultra-thin flexible microsystems

- Mechanical flexibility of microsystems (adaptation to curved installation spaces, deformability during use)

- Miniaturization in z-direction

The IFM ...

- covers the complete technology chain (structuring of film substrates, assembly and contacting of ultra-thin components, construction of multi-layer systems).

- ensures reliability under relevant loading conditions.

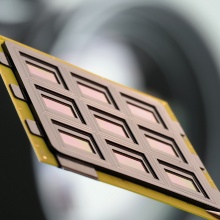

Function integration in three dimensions

- Freedom of design and miniaturization potential through 3D capability

- Integration of mechanical, electrical and optical functions

The IFM ...

- increases the level of sophistication of MID technologies (standardization (e.g. for laser direct structuring), understanding of reliability, improvement of fine-pitch capability).

- expands the range of thermoplastics to include ceramics and thermosets (used in harsh environments).

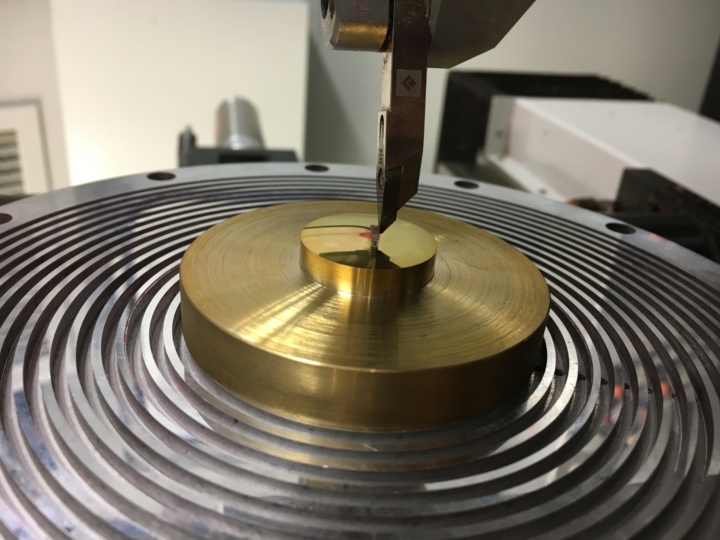

High precision structuring processes

- Development of innovative microtechnical products

- Realization of optical, electronic and / or mechanical functions

The IFM ...

- utilizes and combines different processes for direct manufacturing of components (laser processes, wet chemical metallization, printing processes, high and ultra precision machining, MEMS structuring processes and galvano copying techniques).

- integrates microstructured components into injection molding and molding tools (replication in plastics).